Good Construction Practices

At Bharathi Cement, we are obsessed with quality. Our cement is tested at every stage, from the first to last. Using the world renowned Narzi limestone we produce cement that has higher strength, low manganese and low alkalies.

Today, we bring the same expertise and commitment to quality, as we offer you the following suggestions to make a beautiful home.

Land: A square or a rectangular plot is ideal for construction.

Cement: Use strong and superior quality Bharathi Cement.

Water: Only use clean, pure water. Saline water not just weakens the cement but causes the iron used for construction to rust.

Iron: Use BIS approved iron.

Aggregate: For the columns, beams, foundation and slab use stone with 20mm thickness.

Sand: It is best if you use clean, dirt-free sand.

Foundation: Keep in mind the nature of the land and soil where you’re building your house.

Plinth level: The height of the current road level and any future changes to this level will help determine the optimum plinth level.

More tips

- Do not use black soil under the flooring

- Apply primer/tar behind the door frame

- There should be some gap between the slab and the water tank

- If you need to do plastering on the slab, it's best right after putting the slab

- The height of a stair should not be more than 15 cms

Bricks and Brick work:

- For a wall of 9 inches thickness, the mixture should be of the ratio 1:6 (1 cement:6 sand).

- Use the cement, sand and water mixture within 45 minutes

- The joint between the bricks should not be one above the other

- If you have to end the length of the wall, do so at an angle of 45 degrees

Plastering:

- Start plastering only after you’ve watered the bricks completely

- Mix cement and sand in the ratio of 1:6 inner plastering - (1 cement:6 sand) outer plastering - (1 cement:4 sand)

- On a brick wall never do plastering of thickness more than 12 or 15mm

- At one go, avoid plastering of more than 12mm thickness

- On concrete do not do plastering of more than 6mm thickness

- Do not plaster on concrete without hacking

- Plastering on concrete should be in the ratio of 1:3

- Use a mesh while plastering the electric and water pipes

Curing

- For the cement to be strong, curing is very essential. You must do the curing for at least 14 days,continuously

- The more curing you do, the better it is

- Slow setting cement is always the best

- The color of cement has nothing to do with the strength of the cement

- If too much water is used, concrete loses its strength

Concrete:

- The ideal ratio of the concrete mixture should be 1:1½:3 (1 cement: 1½ sand:3 aggregate)

- If you use PPC while preparing concrete, for every bag you need to use 24 litres of water

- There should be no gaps in the shuttering. Using oil while shuttering will help

- Always mix concrete using a machine

- Avoid concrete work when the weather is too warm or too cold

- Iron bars should be covered with concrete up to a height of 15mm

- Do not put concrete higher than 5 feet of the columns

- It is advisable to use a vibrator

Suggested Concrete Mix Designs

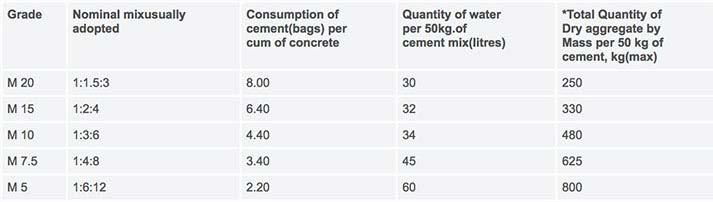

Requirement of cement, water, dry aggregate (both coarse and fine) for different grades of concrete (Nominal Mix) work are given as under

Table 9 Proportions for Nominal Mix Concrete (Clauses 9.3 and 9.3.1) IS 456-2000

*Total quantity= Sum of the individual masses of fine and coarse aggregates, kg

Proportion of fine aggregate to coarse aggregate (by mass) : Generally 1:2 but subject to an upper limit of 1:1.5 and a lower limit of 1:2.5

Note: The proportion of fine aggregate to coarse aggregate should be adjusted from upper limit to lower limit progressively as the grading of fine aggregate becomes finer and the maximum size of the coarse aggregate becomes larger. Graded coarse aggregate shall be used.

Example: For an average grading of fine aggregate (That is Zone II of Table 4 of IS 383) the proportions shall be 1:1.5, 1:2, 1:2.5 for maximum size of aggregates 10mm, 20mm and 40mm respectively

Who we are

Who we are Our Products

Our Products WHAT WE OFFER

WHAT WE OFFER sustainability

sustainability our people

our people